Introduction

You want to try running your RC on water, or the possibility of your servo getting wet is high. Unfortunately, there is no water-proof servo. So, what do you do?

Well, you need to make your servo waterproof.

But then, how to make a servo waterproof?

There are 4 ways to waterproof a servo and the best method is marine grease. Put an O ring on the rotating shaft of the servo. Uncover the servo and take a non-conductive marine grease. Ooze it around the shaft and bottom part of the servo. Put the lids back in and your servo is now waterproof.

There are a few more methods that you can use to waterproof RC servo. In this article, we are going to describe all the sure-fire ways to waterproof a servo.

Without further ado, let’s dive in.

Why Do Water Gets In The Servo

Whether the servo is digital or analog, all servos are water resistant, not waterproof. Hence, when you run an RC in water, there’s always a chance for water to seep inside.

When we think about why water gets into the servo of an RC, there’s a fundamental reason. The reason is that there’s a pressure difference between the outside and inside the servo.

We completely want to mitigate the possibility of water getting in.

Let’s see how we can stop the water from getting in the servo.

4 Ways To Waterproof a Servo

So, to make the servo waterproof, we need to prevent water seepage from happening. What we need to do is fill the servo with incompressible media.

Here are a few methods you can use to waterproof your servo.

Method 1 of 4: Use Olive Oil

Yes, you can use olive oil to waterproof your servo. Olive Oil is an exceptionally good insulator. According to a study, olive works well as a liquid insulator for electric motors.

Because oil never mixes with water as we know. As a result, the olive oil protects the servo from getting damaged by water.

Now that we know olive oil works, follow along to waterproof your servo with olive oil.

First, take off the bottom cover of your servo. There are 4 screws to undo to remove the cover.

Now, take an O-ring and cover the rotating shaft that is on the top of the servo.

Next, you will need a shaft saver to cover the shaft. This will prevent the servo gear train from stripping out.

There are O-ring around the seams of the servo, take them off. Then seal the seams with epoxy to make sure there’s no leak.

Now take a look at the image below –

Put 3 of the 4 screws in on the bottom cover of the servo. With the remaining hole, fill the servo with olive oil. For a clean procedure, use a syringe to fill up the servo with olive oil.

Use the remaining screws to close the lid and clean up the servo.

Congratulations! With that, you have successfully water-proofed your servo with olive oil.

Let’s take a look at some more methods to make a servo waterproof.

Method 2 of 4: Use Marine Grease

For waterproofing the servo with Marine Grease, follow these instructions-

- Uncover the servo’s top cover, exposing the inside of the servo.

- Take off the bottom cover of the servo

- Find a marine grease that is non-conductive

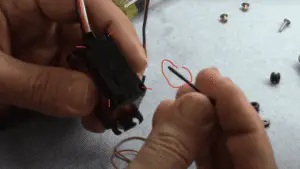

- Ooze out the grease around the rotating shaft as shown in the image

- Completely coat the servo with the grease. Both top and bottom parts of the servo are where chips are placed.

- Use a stick or thin tool to spread the grease.

- Shut the covers of the servo.

- Coat the seams of the covers with epoxy.

Method 3 of 4: Use Liquid Tape

Liquid Tape will completely seal your servo from any possibility of water getting inside the servo.

Here’s how to use liquid tape to waterproof your micro servo –

- Uncover the bottom lid of the servo.

- Spread some black grease around the gears of the servo. This will ensure the proper lubrication of the gears to rotate inside the sealed servo.

- Cover the servo with the lids back on.

- Find a masking take and cover the aluminum of the servo. Aluminum helps to dissipate the heat.

- Spread the liquid tape with a brush all over the servo.

- Let the liquid tape dry to make it waterproof.

Method 4 of 4: Use Acrylic Conformal Coating

Using acrylic conformal coating is the cleanest way to waterproof a servo. Let’s show you how to use the acrylic conformal coating on your servo –

- First, take a screwdriver, and uncover the lids of the servo.

- Take out the screws of the lids carefully.

- Undo the gears of the servo and line them up to remember the order.

- Carefully undo the screws of the servo motor.

- Take the servo motor out of the box

- Apply 2-3 coats of acrylic conformal coating

- Now apply 5-6 coats of liquid acrylic conformal on the electric board of the motor.

- Let the liquid try for an hour.

- Carefully put together the rest of the components of the servo

- Shut the lids back together and screw in the screws.

That concludes the 4 methods you can use to waterproof your servo.

And the methods are easy to follow as we promised at the beginning of the article.

Now, let’s show you how to test the waterproofness of the servo.

How To Test for Waterproof Servo

Now that you know the methods to waterproof your servo, it’s time to test it out.

Here’s how you can test whether your servo is now waterproof or not.

- Fill a bowl with clean water

- Drop your the servo that you made waterproof yourself

- After completely sealing the servo, see if any bubble comes up on the surface of the water.

- And for acrylic conformal coating, try running the servo underwater.

- If the servo is running well, your servos are now completely waterproof.

FAQs

Are servo Motors Waterproof?

Servos are only water resistant, meaning that if water is splashed on the servo by any chance, the water won’t seep inside. But when you submerge the servo underwater, then it is a problem. You’ll have to DIY for having a waterproof servo. There are a few methods for the waterproof servo.

What Causes a Servo to Fail?

Despite their general toughness, coolant, water, and even everyday detritus like dirt, can impair servos. The latter can clog up fans and other crucial system components, which leads to overheating. Liquid impurities may affect the motor’s windings,

encoder, and bearings, among other components.

How Long Do Servo Motos Last?

RC servos can last up to 20 years or more. When maintained and kept in ideal condition, servos can last very long. A good servo doesn’t require much maintenance. Remember to clean up the debris and change the lubricant once in a while. Do not overheat the servo too much and your servo will last.

End Note

A small tip before bidding farewell – make sure to purchase a good quality sealant to waterproof your servo.

So, which method do you like out of the 4 ways how to waterproof a servo?

Don’t forget to let us know how your waterproofing trial goes.

Best of luck!