Technically, brushless motors are more advanced, durable and faster than brushed motors. But this simple theory does not mean that a brushless motor wins the debate. Brushed motors are still more compatible when brushless motors are unfit.

So, the ultimate winner depends on the actual usage and compatibility.

In this article, we will compare both motors, try to understand their strength and weakness and discover which one is compatible for someone.

Read and explore.

Brushed Vs. Brushless RC Motors: The Comparison

Are you unsure which one to pick or want to know their differences? Here is the comparison chart to learn about them at a glance.

| Factors | Brushed motor | Brushless motor |

| Speed | Top speed but slow acceleration. | Top speed and fast acceleration. |

| Power | It provides low power output. | It provides high power output. |

| Heating | It generates more heat during operation. | It generates less heat during operation. |

| Longevity | Limited lifespan comparing brushless motors. | It usually lasts longer than brushed motors. |

| Customization | It offers limited customization options. | It has more customization options. |

| Noise | It comparatively produces more noise. | It is generally quieter. |

| Skill required | It is beginner friendly, requiring no advanced operating skills. | It requires to have technical knowledge and expertise. |

| Application | Best for slower RC vehicles. | Ideal for high-end RC cars. |

Now it is time to go into detail about both RC motors. Read the following sections and learn more.

Brushed RC Motors

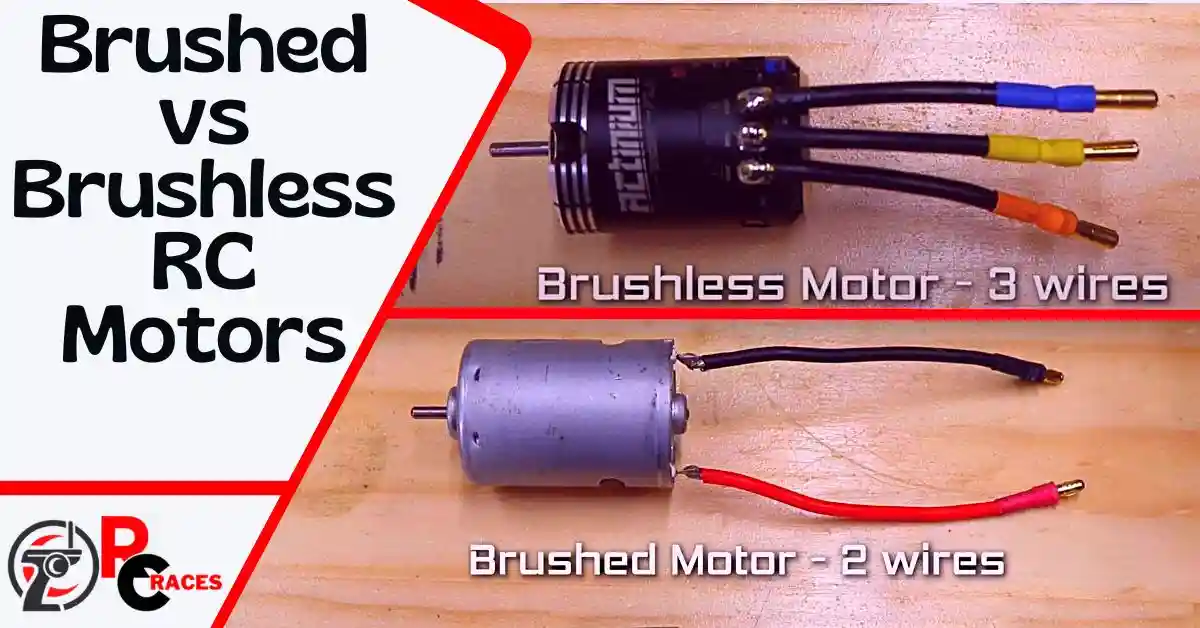

Brushed motors are very common in RC vehicles, particularly in crawlers. They are designed with a rotor and a set of magnets. Besides, their working principles depend on the brushes and the commutators. The brushes used in the motor are made of carbon or graphite.

When the motor is connected to electricity, the current goes through the brushes and creates a magnetic field. It interacts with the magnets in the stator and forces the rotor to spin. This is the process of how the brushed RC motors generate mechanical power.

Components and Construction:

Rotor: This is the spinning part of the motor, consisting of a shaft and wire windings.

Commutator: It is a metal cylinder with contact with the armature. The brushes in the motor make contact with the commutator to flow current to the rotor windings.

Brushes: They are made of carbon or graphite to conduct electricity and continue contact with the commutator sections.

Stator: This motionless part of the motor consists of permanent magnets to create a magnetic field.

Advantages of Brushed Motors:

- They have simple working mechanisms which make them suitable for beginners or users preferring an uncomplicated setup.

- they are compatible with vehicles requiring slower and more precise movements because they provide better low-speed torque.

- They are cost-effecting compared to brushless motors.

Disadvantages of Brushed Motors:

- They may need more maintenance compared to brushless motors. Regular inspection and replacement of the brushes can be a hassle.

- They have low power output than brushless motors.

- They are less durable since the brushes and commutators wear down over time.

Brushless RC Motors

High-performance RC vehicles, particularly racing cars, usually come with brushless motors. They are called brushless since there is no brush inside. Rather they have ESCs (Electronic Speed Controllers) that control the current flow to the motor windings.

These motors use permanent magnet rotors and stators with multiple coils for functioning. The ESC quickly transfers the current flow to different coils during the operation. Thus it creates a spinning magnetic field which turns the rotor and generates mechanical force.

Components and construction:

Rotor: The spinning part of the motor consists of permanent magnets. The rotor is attached to a central shaft.

Stator: This motionless part of the motor consists of multiple coils that generate the magnetic field.

ESC (Electronic Speed Controller): It controls the power supply to the motor and transfers the current to different motor windings.

Advantages of Brushless RC motors:

- They offer better overall performance and provide higher power output than brushed motors.

- Using them is hassle-free since they require no or less inspection and maintenance.

- Their advanced design reduces wear and tear and makes them durable compared to brushed motors.

Disadvantages of Brushless RC motors:

- They have limited torque, which will not provide precise and controlled low-speed movement.

- They may require a complex setup. Also, you may need to have technical knowledge and expertise to configure and program them.

- They are expensive compared to brushed motors.

Performance Comparison: Brushed vs. Brushless RC Motors

Both are unique types of motors with different speeds, power, mechanisms and durability. So, no doubt that the performance of a brushed and a brushless motor will be different. Here is their performance comparison in short.

1. Speed and acceleration

When the speed and acceleration of a motor come into the discussion, brushless motors are far ahead of brushed motors. Brushless motors have advanced designs which provide higher RPM and acceleration.

2. Power and efficiency

Brushless motors convert electrical energy into a mechanical force better than brushed motors. They also have less internal friction. Thus, brushless motors lose less energy and provide higher power output and performance.

3. Heat generation

In brushed motors, brushes and commutators create friction which generates heat. That’s why using one may require a cooling system based on the situation. On the other hand, brushless motors have a low-friction design that generates less heat. So, they usually do not require a dedicated cooling system.

Based on the heat generation during operation, brushless motors are more reliable in high-performance RC vehicles.

4. Durability

Due to unique mechanisms, the durability of both motors is also different. Since brushed motors have wearable components, they are less durable by nature. They may require frequent maintenance and replacement.

On the other hand, brushless motors generally require less maintenance since no brush or other wearable components are inside. For this reason, brushless motors also have a longer lifespan.

Which One Is Right For You?

After reviewing the detail of the two motors and performance comparison, you should have found which meets your needs. Cannot you still decide? Check the following points for quick decision-making.

Go for a brushed motor if:

- You are just starting your RC journey.

- Your budget is limited.

- You have a slower vehicle requiring precise movement, like a rock crawler.

- You have no plan for future upgrades or customization.

Go for a brushless motor if:

- You already have some experience with RC cars.

- You have a high-performance vehicle, like a fast-racing RC car.

- You have the technical knowledge and expertise to handle the motor.

- You want more upgrades and customization in the future.

Frequently Asked Questions

What is the speed and acceleration of an RC motor?

The speed of a motor means how fast it rotates. RPM measures the rate of the rotation. In contrast, acceleration means how fast the motor can increase and decrease the rotational speed. Brushless motors have better speed and acceleration compared to brushed motors.

Can I replace a brushed motor with a brushless one?

You cannot replace one with the other unless you modify your RC vehicle significantly.

Final Words

The article clearly shows that both brushed and brushless RC motors have many advantages and disadvantages. However, they are unique in many aspects and suitable for particular purposes. Whether you are a beginner or advanced user, choose one that meets your specific needs, expertise level and budget.